Virtual Power Plant

Dennis C. Cossey, CEO of Impact Strategies Inc has written this paper focusing on a hybrid, fuel-flexible, enhanced minigrid scale system which is defined here as a DER system capable of generating power in the 5 to 10 megawatt range (although it can be designed to accommodate virtually any output). This is enough power to supply peak demand for a small industrial center as well as the local supporting community infrastructure on a 24/7/365 basis.

April 20, 2018. By Moulin

POWER SECTOR

Virtual Power Plant

Dennis C. Cossey, CEO of Impact Strategies Inc

Dennis C. Cossey, CEO of Impact Strategies Inc has written this paper focusing on a hybrid, fuel-flexible, enhanced minigrid scale system which is defined here as a DER system capable of generating power in the 5 to 10 megawatt range (although it can be designed to accommodate virtually any output). This is enough power to supply peak demand for a small industrial center as well as the local supporting community infrastructure on a 24/7/365 basis.

Executive Summary

Energy, in the form of electricity, is the essential building block of economic viability, whether to expand an already established economic system or as a platform providing sustainable growth for developing nations. For almost as long as civilization has been el`ectrified, power has been provided by large centralized utilities broadly distributed via high voltage transmission grids.

Unfortunately, these grids are sclerotic and not designed to reach rural locales, leaving hundreds of millions of global stakeholders without access to electricity. The International Energy Agency (IEA) estimates that nearly 1.3 billion people - over four times the population of the US - mostly in Africa and South Asia live without power. Fairness demands these populations gain access to electricity and the benefits it can provide: health, education and economic opportunity.

Moreover, almost as many people have only intermittent access to power, suffering regular power outages for hours or days at a time. Further, IEA estimates that nearly 1 billion people will still be without access to electricity in 2030, unless power access alternatives are forthcoming.

Governments, who continually struggle to remedy this situation, are coming to realize the established energy paradigm of building mega power stations coupled to vast inflexible utility grids are not the answer. Cost, together with rapid population growth, is outrunning their ability to deal with the situation through reliance on conventional market-led approaches.

Although no single silver bullet can solve the problem overnight, new developing technologies present several viable options which show great promise to mitigate the challenge and create tremendous socio-economic opportunities to not only expand a country's electric-powered industrial base but also raise the standard of living.

One of these options is the Virtual Power Plant (VPP) concept that can effectively aggregate various power generation inputs into a coherent source of energy to provide a reliable and cost-effective power source tailored for smaller, clearly defined local or regional customer bases.

The key component of the VPP is the development of advanced software, or "smart controls," capable of managing a variety of resources for a system’s power generation, transmission, storage, and delivery. Most VPP's involve management of technologies typically residing in small local grid systems known as microgrids and minigrids, the relationship of which is described in the following sections.

Minigrids, Microgrids and Virtual Power Plants

Both minigrids and microgrids typically function as scaled down versions of primary or mega utility (a/k/a legacy) grids but on a considerably smaller, more dynamic and more focused scale.

At their essence, they are self-contained electrical ecosystems supplying power that is produced, transmitted and consumed on a local scale. They are capable of servicing designated local grids as fully self-contained entities, i.e. stand-alone systems; or they can be integrated into larger, central utility grids, while still fully capable of operating independently if disconnected from the primary grid.

More simply, a minigrid or microgrid is comprised of a single source or combination of power generation sources – also referred to as Distributed Energy Resources or DER's – that can be harnessed through a central 'smart software' center which functions as a virtual power plant capable of supplying electricity to a defined local customer load base.

Enhanced Minigrid - Emission-Free, Reliable Power Generation

Typically, most minigrids are comprised of two power generation sources:

1) Solar panels, and

2) A fossil fuel genset.

Updated versions include a second renewable source in the form of wind power (atmospheric conditions permitting) as well as an energy storage option. One advantage of renewable resources is the ability to generate power in remote locations where a traditional power grid is unavailable; and these new systems can take advantage of an emission-free configuration, beginning with no smokestacks.

Because the wind does not always blow nor the sun always shine, there will be recurring power "outages"; and there are several available options to fill in the outage gaps, namely:

- Fossil Fuel component (e.g. heavy oil, coal, pet coke, natural gas, biomass)

- Energy Storage component (from several technologies)

- Combined Heat Power component (CHP)

- Hydro component

- Geothermal component

While four of the five options meet sustainable emission requirements, two of the four – hydro and geothermal – are limited to geographic availability and output intensity factors, thus not universally available.

Energy generated by CHP, wherein waste heat generated from a third-party sources such as manufacturing, waste-to-energy, or sewage plant digesters, could be considered sustainable in and of itself, however the sustainability designation must include the source of the heat generated, which may or may not be emission-free.

The fourth option – energy storage technologies – has great potential for smoothing out or buffering the electricity supply from renewable energy sources, thus ensuring real-time supply/demand match. Balancing the ever-changing dynamic of supply vs. demand is critical for a more reliable and cost-effective power grid. Energy storage options currently being utilized include:

- Lithium Ion batteries

- Sodium Sulfur batteries

- Lead Acid batteries

- Flow batteries

- Pumped Hydro

- Others (flywheel, compressed air, etc.)

While each of these energy storage options meet environmental expectations, each has certain operational pluses and minuses.

In addition, some of these storage options represent technologies-in-progress, which means costs are an ever-fluctuating consideration that will drive the utilization decision, especially for developing/expanding economies.

However, much like wind and solar, on-going research and development will continue to reduce the cost and durability of storage options allowing them to continue to be a valuable asset to utility grids in the future.

The remaining option is the inclusion of a fossil fuel component, which many see as a necessary to ensure minigrid reliability by supplying on-demand power when power from renewables is either diminished or totally unavailable.

The fossil unit could be utilized as an integral part of the VPP, functioning as an around-the-clock power source supporting the renewable components; or it could function on a stand-by basis as a "peaker" plant. Either way, a fossil fuel plant, operating alone or in conjunction with an energy storage system is a key element for a fully reliable minigrid.

The ultimate challenge for existing fossil fuel plants is managing environmental restrictions based on newly established global standards for emission-free power generation. Thus, pretty much any conventional fossil power configuration cannot sustainably operate in a minigrid system due to toxic air emissions that include: CO2, NOx, SOx, mercury, and particulates (sub 2.5μ).

While there are a number of post-combustion capture technologies currently in use, they represent a serious parasitic power load on the plant, are expensive to integrate, and simply reduce rather than eliminate toxic air pollutants. In fact, virtually all post-combustion technologies typically address a single pollutant rather than multiple pollutants, further diminishing any cost/benefit advantages

While the use of fossil fuels as a power source is winding down on a global basis, some countries will, by absolute physical necessity, need to rely on fossil fuels for the foreseeable future. In those areas, the power infrastructure will remain dependent on fossil fuels due to sizeable coal, natural gas and oil reserves and low extractive costs associated with their availability and use.

Even in the face of serious public health issues and the well-documented threats of an overheated planet, many emerging economies struggle to transition from fossil to renewable energy sources. Competitive pressures, especially in developing economies, make it virtually impossible to eliminate the use of fossil fuels within the next 15 to 20 years at a minimum.

It is believed that the THOR technology, by replacing conventional fossil fuel combustion with its zero air emission process, would help solve life-threatening pubic health problems; serve to smooth the transition from fossil to renewable energy stocks; and make an important contribution to reducing the threat of climate change.

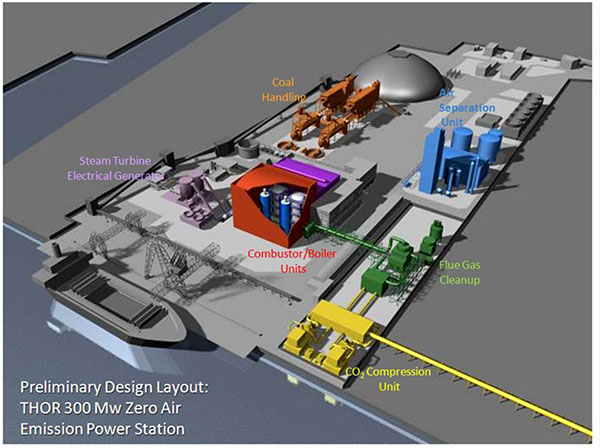

300Mw THOR plant

Therefore, should fossil fuels remain necessary to meet the world's current and future energy needs, in order to avoid catastrophic climate events, it is vital they meet the following criteria:

- Combust at an affordable price,

- Emit no toxic air emissions, and

- Effectively recycle all combustion by-products into inert or beneficial reuse formats.

Only then should the use of fossil fuels be considered productive or even, in many cases, allowed to continue to be used.

The inclusion of THOR in the energy mix for future minigrid systems will allow them to remain cost-effective, maintain ultimate reliability and ensure environmental integrity.

Pressurized Oxycombustion and Virtual Power Plants

Historically, the combustion of fossil fuels (primarily coal prior to 2014) was done inside a vessel under atmospheric conditions. Air and fuel were heated to the point of combustion which created steam to power turbines that made electricity. Excess by-products were vented into the air through a smokestack. Approximately 30 years ago this practice became unacceptable due to serious issues associated with venting; and discharging poisonous pollutants into the atmosphere. It also began driving markets to find solutions to these troubles.

One of the options was atmospheric oxy-fuel combustion; a process of burning fossil fuels at atmospheric conditions using pure oxygen instead of air as the primary oxidant. Since the nitrogen component of air is not heated, fuel consumption is reduced, and higher flame temperatures are possible. Atmospheric oxy-fuel combustion chemistry has been successfully used for decades in industrial applications such as aluminum smelting, welding and cutting of metals, glass making, etc.

Atmospheric oxycombustion has also been tried at various times as a replacement for power generation for conventional fossil fuel power plants. Although it worked well as a combustion process and as an air pollutant reduction technology, the economics made it impractical as a widely used technology by utilities.

However, when elevated pressure was introduced into the oxycombustion process, the technology's performance and economics improved dramatically. Thus, the development pathway--- from atmospheric oxycombustion mixed with oxygen, to pressurized oxycombustion with its improved efficiency-- greatly reduced the footprint and lowered cost, resulting in a step-change, or paradigm shift, in power generation.

One of the first such technologies is a pressurized oxycombustion process known as the THOR CleanPower process (THOR).

THOR represents a totally different thermodynamic approach to conventional power plant design. Based on well known and reliable atmospheric oxycombustion chemistry, it combines the combustion of any carbon-based fuel with essentially complete recovery of all by-products, including CO2, NOx, SOx, Hg, and particulates.

The key element that separates THOR from conventional oxyfuel designs is that combustion takes place at optimum pressures between 300 psi and 1,300 psi. Increasing the pressure of combustion shifts the temperature at which water, CO2, mercury and acid gases condense. Managing gas-to-liquid nucleate condensation physics allows for the complete removal of pollutants while recovering CO2 as a pressurized liquid ready for sequestration or reused to produce coal bed methane, enhanced oil recovery or other useful applications. Toxic air emissions from fossil fuel power plants will become a thing of the past.

When combined with renewable energy sources such as solar and wind, THOR now forms the hub of enhanced minigrid power generation which, in turn, combines with the Smart Grid Management system forming the nucleus of a Virtual Power Plant (shown in Figure 1).

Figure 1: Enhanced Minigrid

The interconnectivity provided by a THOR-enhanced minigrid system allows each power generation component to be scaled down in size, because none need to bear the burden of thebulk of the power output required by the minigrid. Each power generation component fulfills its role as designed within a modulated range in the grid’s initial design. Future growth in output requirements can be accommodated in modular increments. The results are a VPP supplied by a smaller, more cost-effective minigrid layout.

Water usage associated with conventional fossil fuel power plants ranges from being a significant to critical issue depending on prevailing geographical conditions. This is an issue that promises to loom larger as the availability of the world's fresh water resources continues to diminish.

Depending on choice of feedstock, THOR's water use ranges from neutral (i.e. it produces the same amount of water that it uses) to net water production. This artifact of the process alleviates the necessity of continually drawing down of local fresh water resources.

THOR not only guarantees grid reliability, but its fuel flexibility offers power plant owner / operators multiple options in utilizing local indigenous resources – especially beneficial in developing countries with significant carbon-based fuel reserves.

Virtual Power Plant Control and Management

The brain of the Virtual Power Plant is its master control system. Machine learning (AI) and the Internet of Things (IoT) have the power to create an increasingly autonomous grid that can eventually handle billions of endpoints within utility networks and minigrids. Having selected the primary sources of energy production based on an enhanced minigrid – i.e. wind, solar and THOR –an equally critical part of grid architecture must be discussed: the hardware/software "smart control" system that forms the heart of the Virtual Power Plant.

This system is responsible for the collection and processing of data and information gathered from all components comprising the minigrid system and processed in a central controller (utilizing cloud-based infrastructure). Then, a control signal is transmitted directly to each agent through supervisory, control, and data acquisition function (SCADA).

SCADA centrally manages the functionality and resiliency of the minigrid, gathering and monitoring virtually every system activity, by integrating system resources to match power generation with demand on a real-time basis.

In addition, SCADA analyzes and manages other critical functions such as fast-ramping (load variability), frequency stability, energy profiling and generation forecasting, dynamic stability control, transient stability control, load-shedding, interchange transaction scheduling and automatic decoupling (should the minigrid be coupled with a larger utility grid).

Historic statistical algorithms are fed into advanced digitalization software coupled with artificial intelligence (AI) systems that continuously optimize current energy flow as well as refine energy forecasting parameters for increased grid security, stability and reliability as well as emergency reaction execution. The objective is to fine tune system integrity and performance which will be fed back into the system for design of future minigrid systems, calibrated to result in lower Capex and Opex costs.

Virtual Power Plant + Enhanced Minigrid Benefits

A VPP built around a THOR enhanced minigrid system offers distinct advantages and benefits to its customer base. Some, but not all, of these benefits include:

- Meets all current and future air emission issues and regulations

- Reduces environmental impact and contributes to public/planetary health

- Provides basis for 24/7/365 grid reliability

- Increases overall grid efficiency through demand aggregation

- Locally controlled and oriented

- Allows use of indigenous carbon fuel resources w/o environmental penalty

- Able to operate connected to main utility grid or operate as a stand-alone grid system

- Net water positive (THOR gas-fired plants produce 1.5 tons of clean water per 1 ton of gas burned

- Increases network operational benefits due to single master control system

o loss reduction

o reduce grid congestion

o voltage control

o increase network security

o optimize operation requirements and energy needs forecasting

o supports smart metering and real-time pricing

o blockchain capable

- Promotes economic growth / helps alleviate energy poverty

VPP's can also be used as a tool to advance socio-economic programs and policies. VPP reliability and output flexibility due to modular design can set up shop virtually anywhere – whether the area is supported by a main utility grid or not. This will allow manufacturing industries to either relocate from over-crowded urban areas or build satellite factories in rural locations where overhead costs are lower and labor is plentiful.

Used as a repowering option for existing fossil fuel power plants, new plant construction, or enhancing minigrids, THOR shows great promise as a game changing technology in the fight against climate change, especially for countries with large fossil resources such as China, India, South Africa, United States, and Australia, among others.

Summary

The VPP based on a THOR enhanced minigrid as described in this paper is not meant to compete with or replace lower output microgrids designed to bring electricity to small villages and communities requiring 500 kW or less in energy needs. These smaller systems serve a critical need in bringing power to those areas too small to justify outdated legacy utility transmission hookups. It is a market that is predicted to grow exponentially over the next decade according to power industry experts.

Nor is an enhanced minigrid intended to compete with multiple megawatt power installations (e.g. solar power parks, fossil fuel stations, etc.) that require hundreds of acres of land, sufficient natural resources (e.g. radiant energy, coal, natural gas) and long, inefficient transmission infrastructures necessary to deliver the power generated.

Rather it is a unique, cost-effective, reliable hybrid energy solution fully capable of supporting rural industrial parks and communities that can reduce participating industry overheads while bringing power to the local community where before there was none, benefiting all stakeholders by creating jobs, improving lives, while simultaneously improving industry margins.

Source: “Virtual Power Plant, Discrete Power Generation Incorporating Enhanced Emission-Free Fuel-Flexible Minigrids.”Dennis C. Cossey, CEO, Impact Strategies Inc.

please contact: contact@energetica-india.net.